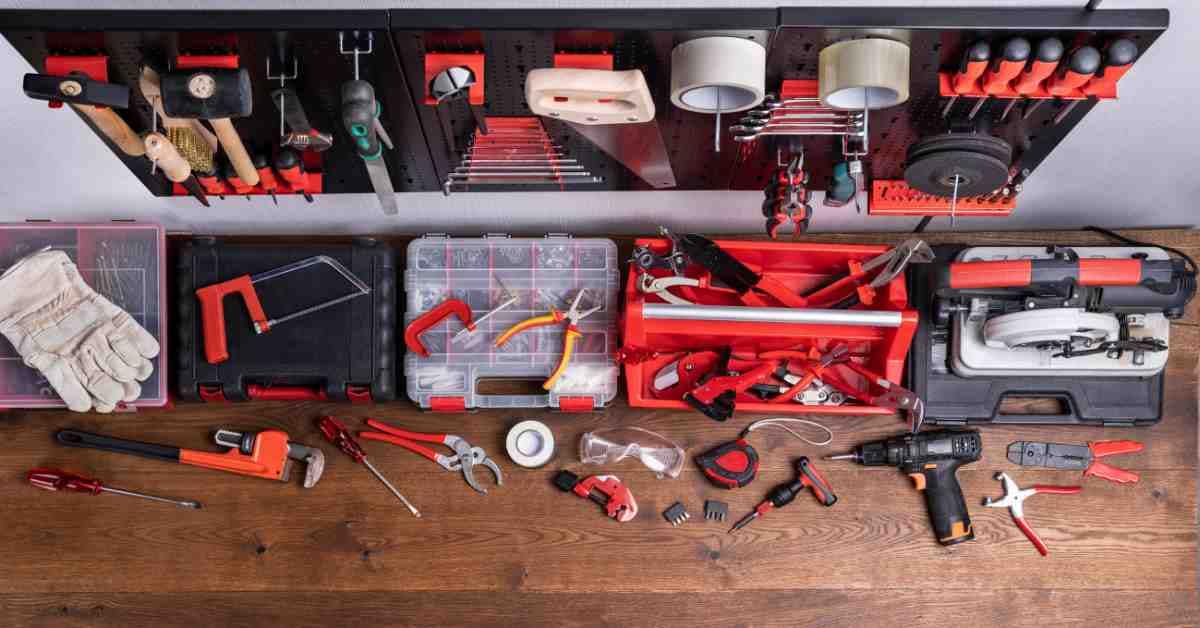

A mechanic set of tools comprises essential equipment for vehicle maintenance and repair. It typically includes wrenches, pliers, screwdrivers, and hammers.

For anyone passionate about automotive work or DIY projects, possessing a quality mechanic set of tools is crucial. These sets not only enable professionals and enthusiasts to tackle a variety of mechanical tasks but also ensure that they can do so efficiently and safely.

The right collection of tools can significantly affect the success of repairs and the maintenance of vehicles, making it a wise investment for longevity and performance.

Choosing a set that offers versatility, durability, and precision is key to handling any mechanical challenge that comes your way, from simple tune-ups to complex engine overhauls. A well-equipped toolbox is the foundation of any mechanic’s arsenal, empowering them to deliver top-notch service and results.

Introduction

A mechanic set of tools is a staple in any DIYer’s arsenal. Essential tools for a variety of tasks are included. Whether you’re an aspiring mechanic or a seasoned DIY enthusiast, a comprehensive set will serve you well.

Why Every Diyer Needs A Good Set

Quality tools make every job easier. A good set can mean the difference between frustration and success. With the right tools, you’ll tackle projects with confidence and precision.

- Durability: Tools that last for years

- Versatility: Tackle multiple types of repairs

- Efficiency: Save time with the right tool on hand

Key Considerations Before Purchase

Before investing in a mechanic tool set, consider your needs.

| Consideration | Details |

|---|---|

| Quality | Look for chrome vanadium or stainless steel |

| Range | Ensure a wide variety of sizes and types |

| Warranty | Check if it comes with a manufacturer warranty |

Remember, a well-curated tool set is a long-term investment. Choose wisely to ensure it meets all your repair needs.

The Core Of Your Toolkit

A mechanic’s toolkit is their best friend. Quality tools lead to successful repairs.

A well-equipped set saves time and hassle. Let’s explore the essentials.

Socket Sets: The Versatile Must-have

No toolkit is complete without socket sets. They fit various fasteners. Their versatility is unmatched.

- Ratchets for quick rotation

- Extensions to reach tight spaces

- Adapters for different drive sizes

Choose sets with SAE and metric sizes. You’ll be ready for any job.

Wrenches: Types And Uses

Wrenches apply torque to turn objects. Know your wrench types.

| Type | Use |

|---|---|

| Combination Wrenches | Bolts and nuts tightening |

| Adjustable Wrenches | Various sizes handling |

| Allen Wrenches | Hex socket screws fitting |

For tough spots, use offset wrenches. They provide clearance for your hands.

Screwdrivers And Bits: Tightening And Loosening

Screwdrivers and bits are essential for mechanics. They tighten and loosen screws. Good sets make jobs easier and faster.

Choosing The Right Screwdriver

The right screwdriver is a must. It fits the screw head perfectly. This prevents damage to the screw. It ensures safety and efficiency.

- Flat-head: For slotted screws.

- Phillips: For cross-shaped screws.

- Torx: For star-shaped screws.

- Hex: For hexagonal recesses.

The Importance Of Bit Variety

Bits need to match many screw types. Variety is key. Different tasks need different bits.

| Bit Type | Use Case |

|---|---|

| Pozi | For high torque application. |

| Hex | For furniture assembly. |

| Torx Security | For electronic devices. |

Quality sets come with a bit holder. It keeps bits organized and accessible.

Pliers And Grippers: Holding And Twisting

Every mechanic knows that having the right tool is crucial. Pliers and grippers are essential for any mechanic’s toolkit. They are perfect for holding, twisting, and manipulating parts. Let’s dive into the types of pliers and features that set quality tools apart.

Different Types For Different Tasks

Not all pliers are the same. Each type serves a specific purpose:

- Needle-nose pliers – Reach into tight spots.

- Wire strippers – Remove insulation from cables.

- Channel locks – Adjust to grip various sizes.

- Locking pliers – Clamp onto bolts or nuts.

- Diagonal cutters – Cut wires and small pins.

Must-have Features In Quality Pliers

Look for these features to identify high-quality pliers:

| Feature | Benefit |

|---|---|

| Non-slip grip | Steady hold, even with oily hands. |

| Durable construction | Long-lasting, resists wear and tear. |

| Precise jaw alignment | Ensures accurate work without slippage. |

| Adjustable settings | Flexibility for different tasks. |

| Rust resistance | Tools stay clean and functional. |

Hammer And Mallet: The Impact Tools

Mechanics know the value of a reliable hammer and mallet.

These tools deliver essential impact force for various tasks. They help in shaping, fitting, and breaking apart items.

Both tools come in different sizes and materials. Each suits specific jobs in the workshop.

Selecting A Hammer For Mechanics

A good mechanic’s hammer must meet specific criteria. It should have a solid head and a comfortable grip.

- Weight: Choose according to the job’s demand.

- Handle: Look for durable materials like fiberglass.

- Head: Steel heads offer durability and strength.

Match the hammer size to the work at hand. A heavy hammer suits large projects. A light one is for precision tasks.

When To Use A Mallet

A mallet differs from a hammer. It has a softer impact. This makes it ideal for sensitive materials.

| Material | Usage |

|---|---|

| Rubber | For delicate surfaces to prevent damage. |

| Wooden | For woodworking and assembling furniture. |

| Plastic | For automotive jobs to avoid sparks. |

Use a mallet when precision is key. It gently shapes materials without leaving marks.

Specialty Tools For Specific Repairs

Working on cars requires more than just a basic toolset. Certain repairs need specialty tools. These tools ensure tasks are done correctly and safely. Let’s dive into some of these essential items.

Torque Wrenches For Precision

Torque wrenches are a must for automotive work. They tighten bolts to specific levels. This prevents damage from over-tightening. Mechanics rely on them for engine work and tire changing.

- Click-type: Gives a sound when the set torque is reached.

- Beam-type: Shows torque reading on a scale.

- Digital: Provides a digital reading and often an alert.

Multimeters For Electrical Diagnostics

Multimeters diagnose electrical problems in vehicles. They measure voltage, resistance, and current. This helps fix issues in wiring, sensors, and batteries.

| Function | Description |

|---|---|

| Voltage | Checks power in electrical components. |

| Resistance | Finds breaks in wires or electrical paths. |

| Current | Measures flow of electricity. |

Storage Solutions: Keeping Your Tools Organized

Storage Solutions: Keeping Your Tools Organized is essential for any mechanic. A neat workspace leads to efficient repairs. With the right storage, finding the right tool becomes easy. Let’s explore the best ways to store your mechanic set of tools.

Toolboxes Vs. Tool Chests

Choosing between a toolbox and a tool chest depends on your needs.

- Toolboxes are compact and great for beginners. They fit in tight spaces.

- Tool chests offer more space and organization. Perfect for pros.

Consider the size of your tool collection and workspace before deciding.

Portable Options For On-the-go Repairs

For mechanics on the move, portable storage is key.

- Rolling tool bags are easy to carry and store essentials.

- Small toolboxes fit in vehicles for quick fixes.

Choose based on the tools you need and how far you travel.

| Storage Type | Best For | Pros |

|---|---|---|

| Toolboxes | Beginners | Compact, Portable |

| Tool Chests | Professionals | Spacious, Organized |

| Rolling Bags | Mobile Mechanics | Easy to Carry, Accessible |

| Small Toolboxes | Quick Repairs | Vehicle-friendly, Efficient |

Maintaining Your Mechanic Tools

Maintaining your mechanic set of tools is crucial for longevity and performance. Proper care keeps them ready for any task. Let’s explore how to keep your tools in top shape.

Routine Cleaning Tips

Clean tools work best. Dirt and grime affect performance. Follow these steps for routine cleaning:

- Wipe tools after each use with a clean cloth.

- Use a mild detergent for a deeper clean.

- Dry tools thoroughly to prevent moisture buildup.

- Inspect tools for damage during cleaning.

- Store tools in a dry, organized toolbox.

Preventing Rust And Wear

Tools last longer without rust. Protect your investment with these tips:

- Apply a light oil coat to metal parts regularly.

- Keep tools in a low-humidity environment.

- Use silica gel packs in your toolbox to absorb moisture.

- Avoid extreme temperatures that cause expansion and contraction.

- Replace worn parts to extend overall tool life.

Expanding Your Toolkit

Every mechanic loves new tools. Expanding your toolkit means more possibilities. It’s like unlocking new skills. Knowing when to upgrade and exploring new tool technologies is key. Let’s dive in.

When To Upgrade

Tools don’t last forever. Signs you need an upgrade:

- Tool is rusty or broken

- Struggling with a job it used to do easily

- Newer models offer more safety

Upgrading at the right time keeps work smooth and safe.

Exploring New Tool Technologies

New technologies make work easier. Here’s why you should pay attention:

- Speed: New tools work faster.

- Safety: They’re safer to use.

- Precision: They make work more accurate.

Always look out for the latest in tools. It’s a game changer.

Frequently Asked Questions

Craftsman, DeWalt, and Snap-On are highly regarded for manufacturing the best mechanics tool sets, known for quality and durability.

Essential tools for mechanics include wrenches, screwdrivers, pliers, a hammer, a multimeter, and a socket set. They also need a torque wrench, an oil drain pan, and reliable work gloves.

A mechanic may spend between $5,000 to $50,000 on tools throughout their career, with costs varying based on specialty and quality.

A mechanics set is a collection of tools including wrenches, sockets, and ratchets, designed for repairing and maintaining mechanical equipment.

Conclusion

Selecting the right mechanic tools is crucial for any repair job. A comprehensive set ensures efficiency and safety. Remember, quality trumps quantity – invest in tools that last. With the right set, you’re equipped for success. Keep building your collection and tackle every mechanical challenge with confidence.